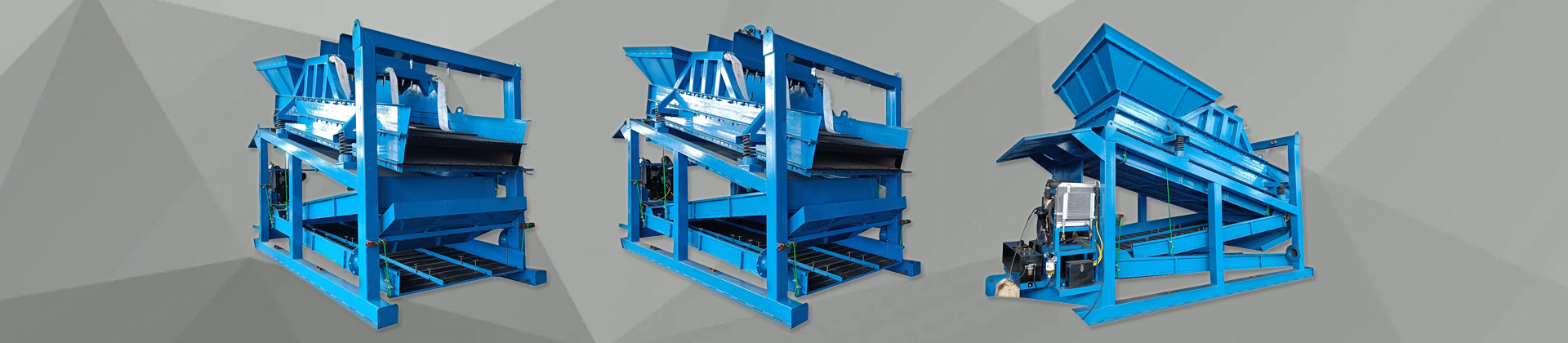

High Capacity mobile gold washing plant(belt type)

1.Features:

1. Compact,mobile concentrator, easy to move and operate;

2. This machine is the most advanced and efficient small scale mining equipment ;

3. great recovery rate down to ultra-fine particles ;

4. Can do continuous process, advanced spiral system, increase gold recovery rate, reduce operator;

5. Portable, simple structure, easy operation, low operating cost.

2. Specification:

Capacity of HPC machines is defined according to the rate at which they will consume / process a stockpile of raw feed material (“Run of Mine” or “Bank-run” material). This is material typical of Placer deposits which contain large and small rocks, gravel, stones and sandy material. Processing capacity is limited primarily by the fraction of undersize material screened from this raw feed and fed onto the HPC’s Concentrator Belt. Accordingly, should you feed the HPC machine with material which is already undersize (or the deposit you are processing consists mostly of fine/sandy material), all of this material will pass directly to the concentrator belt and the effective operating capacity of the machine will be based on this.

Please refer to the attached Production Capacity Tables and Material Flow Diagrams for capacity information corresponding to the material to be processed.

Integrated Feed Conveyor & Feed Material

• Hopper capacity is 0.2m3 (7 cubic feet) and is fitted with a detachable, horizontal Grizzly to remove +75mm (+3'') material.

• Feed Rate is fully controllable by a combination of Variable Speed Drive to adjust conveyor speed and bolt-on choke plate to allow for complete flexibility of material sizing.

• Hopper can be fed manually or using a mini-excavator.

Drive system

• Concentrator Belt and Trommel drive system: 1.5kW (2.0 HP) 3-phase Drive Motor with Reduction Gearbox.

• Integrated Feed Conveyor drive system: 0.4kW (0.5 HP) 3-phase Drive Motor with Reduction Gearbox.

• Each motor is controlled by a Digital Variable Frequency Controller housed within a waterproof enclosure. Note: Single-phase power supplied to the HPC-15 is supplied directly to the Variable Frequency Controllers which convert the power to 3-phase power required by the Drive Motors. The first Variable Frequency Controllers can be adjusted to set the speed of the Concentrator Belt and Scrubbing / Screening Trommel and the second Controller and be adjusted to set the Feed Rate of the Feed Conveyor.

Electrical

Supply

Requirements

Electrical Supply must be Single Phase 220V - 240V and 60Hz / 50Hz.

The motors on the HPC-15 have a combined rating of 1.9kW. When considering startup 1 “inrush” current, we recommend a minimum of 5VA or 6kW Generator (excludes power required for electrical water pump). HPC-15 is supplied with Electrical Supply cable. Note: Electrical Generator is not supplied with the HPC-15.

Water supply requirements

The HPC-15 requires water supply of approximately 40 gallons/minute (160 liters/minute) at a pressure of approximately 45psi (310 kPa). Any electrical, petrol or diesel powered pump capable of providing this water flow may be used. The Water Supply must be connected via a 2” hose (“lay-flat” or discharge hose) clamped onto the inlet nipple on the Water Manifold. Note: Water Pump and connection hose are not supplied with the HPC-15.

Feed material

Maximum: 6” (150 mm) minus material. Recommended: 3” (75mm) minus.

Trommel

Scrubbing & Screening Trommel is 2.8m long with 0.4m diameter and 1.65 m 2-stage Scrubber. Screen is 8mm.

Dimensions

Length 5.63m, Width 1.76m, Height 1.80m, Weight: 1,700 kg

Shipping info

Optimal shipping configuration: 1 X HPC-15 in 20’ container. International customs code: HS #: 8474.10.00 (1) Sorting, screening, separating or washing machines

Trailer

Single-axle trailer with Pintle-hitch (40mm /1.6’’ ID) - Ball Hitch available - to be specified on order.

Manning

1 equipment operator required.

Note: for safety reasons, it is always best to have at least 2 people present when operating machinery.